en

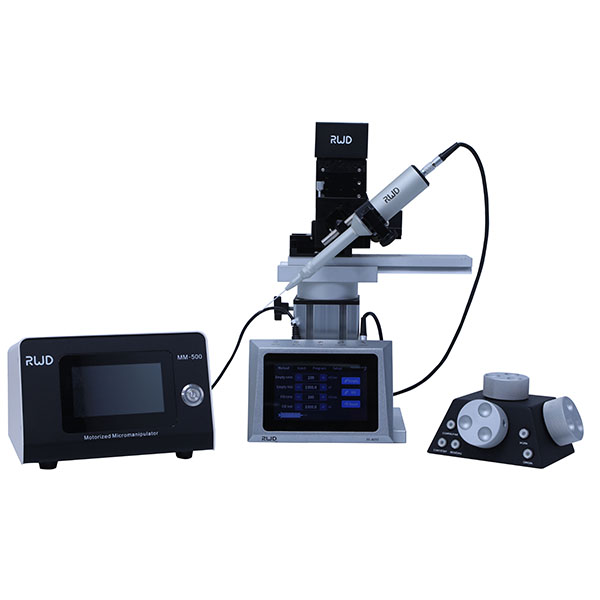

R-480 Nanoliter Microinjection Pump

Brand: RWD

The R-480 is designed for high-precision microinjection, with nanoliter volume injection using fine glass capillaries. Precise control of the internal plunger, coupled with a unique seal ring design, makes better air-tightness, ensuring the accuracy and consistency of injection.

Applications:

Rodents: Stereotaxic injection of drugs, viruses, neurotransmitters or dyes into deep brain tissue in rats and mice.

Fish and Frogs: Embryo/larvae injection of zebrafish clawed toad and other model organisms with nucleic acid material, protein, and dyes.

Insects: nematodes, worms, fruit flies, cotton bollworms, rice lice, etc.